Porsche 356 used for their transmissions a "6 bolt carrier". This was similar to the VW carrier but did not have the VW casting identification.'

As horsepower increased over the years, the ring gear carrier started to show problems due to higher stresses. The ring gear carriers started to crack

along the retaing pin (for the spider gear shaft) axis. This was a very common problem for all the 356 up to ther end of 1961 (approximately).

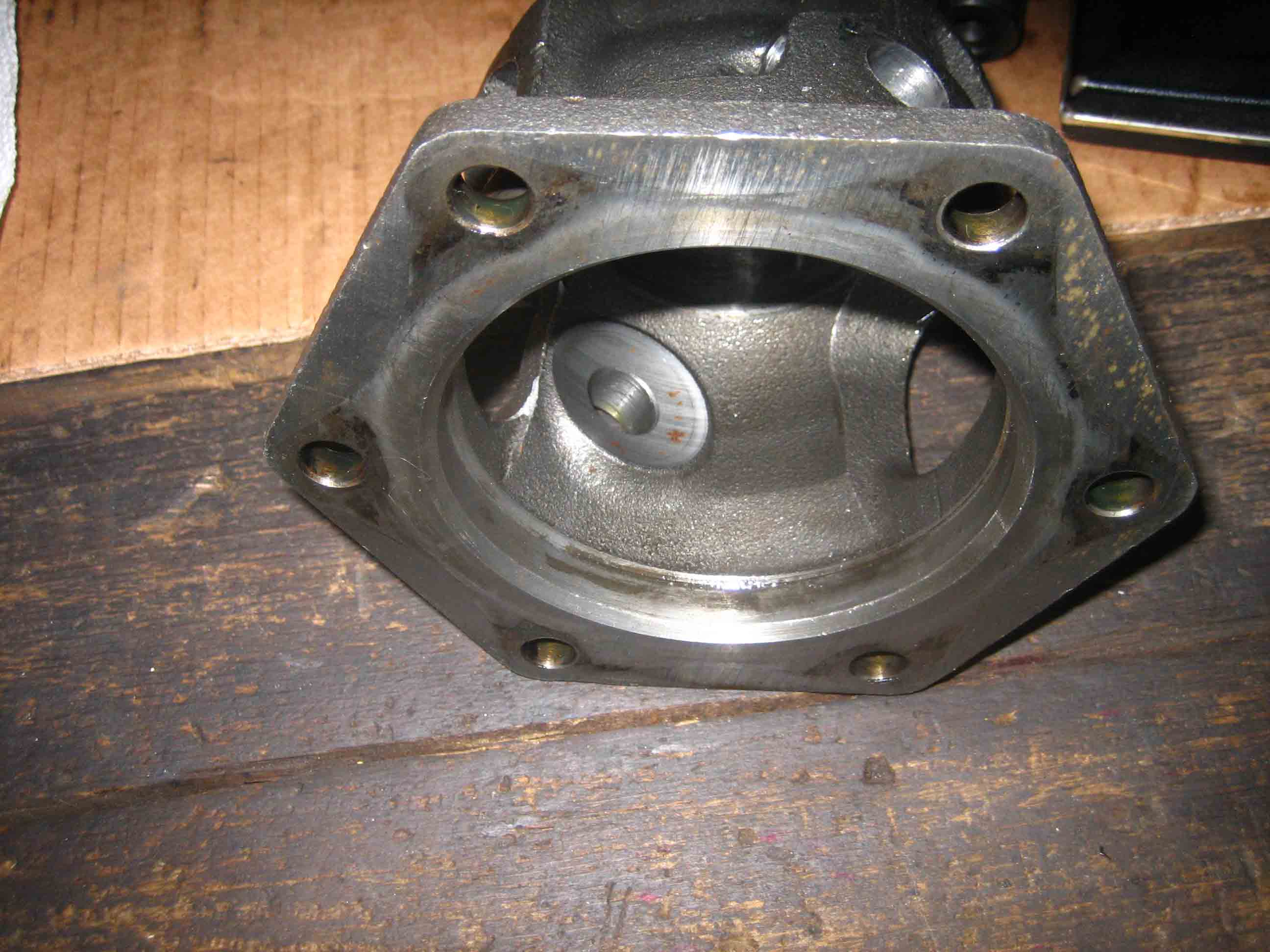

See 6 bolt carrrier

\

bottom view

See picture cracked carrier

>

In the extreme the cast iron would break apart and metal shards would go everywhere and cause massive damage. To alleviate the problem, Porsche increased the diameter of the carrier housing by 3mm.

Picture of new carrier

An additionasl problem that surfaced with the 6 bolt carriers was the failure of the ring gear bolts. The early bolts were of a 10K hardness. They fractured from the stresses. The special locks that fitted around the annular groove in the head of the bolt saved the gearbox from massive failure on some instances.

See Picture broken bolt. Note broken bolt head is retained by Porsche lock saving the ring and pinion from damage in this situation.

To additionally solve this issue Porsche also changed the carrier and ring gear to a 12 bolt carrier and 12 bolt ring gear. The new bolts were of a 12k hardness assembled with a higher torque rating. Clearances were tight in the gear box. The ring gear carrier (with the ring gear) ran at 90 degrees underneat the mainshaft. However the new 12 bolt carrier wouldn't fit under the mainshaft. It was bigger. Porsche notched the mainshaft to accomodate the new design carrier. The mainshaft was originally 22mm diameter at this point. Porsche necked the mainshaft down to 16mm diameter at this point/to fit the new carrier in place.

Picture original mainshaft (1962) with notch.

early mainshafts (1958 and 1960)

Picture of fitment of shaft notch over carrier

Note the notching is done to create clearance for the larger diameter ring gear housing.

As mentioned above, the notch narrors the diameter from 22mm to 16mm. Measuring from the nose of the mainshaft the notch starts at 185mm and ends about 220mm. The radiusof curvature of the notch is 53.25mm